Understanding Robot Certification for Safe Ownership

- Ralph Liu

- 5 hours ago

- 5 min read

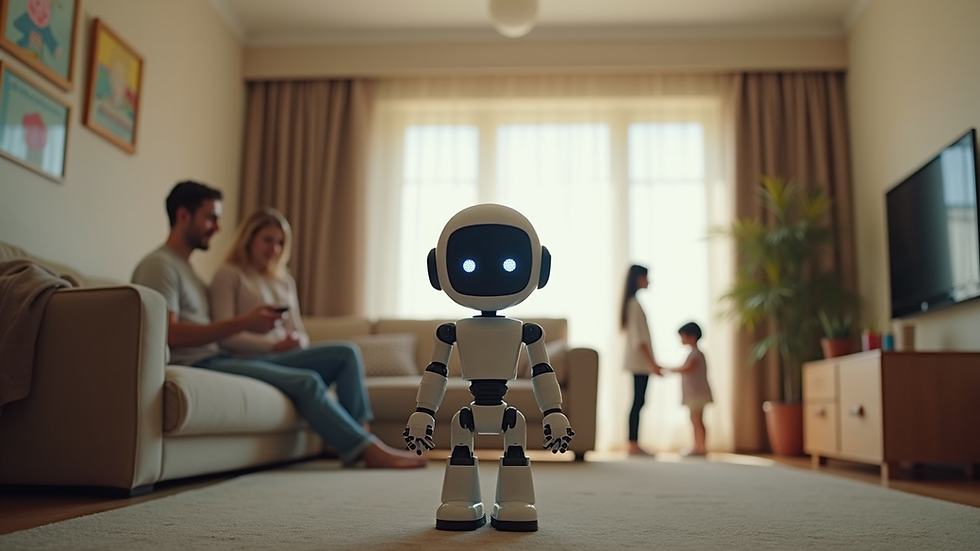

In an era where technology is rapidly evolving, the integration of robots into our daily lives is becoming increasingly common. From household assistants to industrial machines, robots are designed to enhance efficiency and improve our quality of life. However, with this rise in robotic technology comes the critical need for safety and compliance. Understanding robot certification is essential for anyone looking to own or operate a robot safely. This blog post will explore the importance of robot certification, the certification process, and how it impacts safe ownership.

The Importance of Robot Certification

Robot certification is a process that ensures robots meet specific safety standards and regulations. This certification is crucial for several reasons:

1. Safety Assurance

The primary goal of robot certification is to ensure the safety of users and the environment. Certified robots undergo rigorous testing to verify that they operate safely under various conditions. This includes evaluating their mechanical and electrical systems, as well as their software.

2. Compliance with Regulations

Different countries have established regulations governing the use of robots. Certification helps manufacturers and users comply with these regulations, reducing the risk of legal issues. For example, in the European Union, the Machinery Directive outlines essential health and safety requirements for machinery, including robots.

3. Consumer Confidence

When consumers know that a robot has been certified, they can trust that it has been tested for safety and reliability. This confidence can influence purchasing decisions, making certification a valuable marketing tool for manufacturers.

4. Liability Protection

In the event of an accident involving a robot, certification can provide a layer of protection for manufacturers and operators. If a certified robot malfunctions, it may be easier to demonstrate that the manufacturer followed safety protocols, potentially reducing liability.

The Certification Process

The robot certification process typically involves several key steps:

1. Design Review

Before a robot can be certified, its design must be reviewed to ensure it meets safety standards. This includes evaluating the materials used, the design of mechanical components, and the software architecture.

2. Testing

Once the design is approved, the robot undergoes a series of tests. These tests assess various aspects of the robot's performance, including:

Electrical Safety: Ensuring that the robot's electrical systems are safe and do not pose a risk of shock or fire.

Mechanical Safety: Evaluating the robot's physical components to prevent injuries from moving parts.

Functional Safety: Testing the robot's software to ensure it behaves as expected and can handle unexpected situations.

3. Documentation

After testing, manufacturers must provide documentation that details the robot's design, testing procedures, and results. This documentation is crucial for the certification body to evaluate the robot's compliance with safety standards.

4. Certification Issuance

If the robot passes all tests and meets the necessary requirements, the certification body issues a certificate. This certificate indicates that the robot is safe for use and complies with relevant regulations.

5. Ongoing Compliance

Certification is not a one-time event. Manufacturers must ensure that any changes to the robot's design or functionality do not compromise safety. Regular audits and re-certification may be required to maintain compliance.

Key Standards and Organizations

Several organizations and standards govern robot certification. Understanding these can help owners and manufacturers navigate the certification landscape.

1. ISO 10218

The International Organization for Standardization (ISO) has established ISO 10218, which outlines safety requirements for industrial robots. This standard covers both the design and use of robots, ensuring they operate safely in industrial environments.

2. IEC 61508

The International Electrotechnical Commission (IEC) developed IEC 61508, which focuses on functional safety in electrical, electronic, and programmable electronic safety-related systems. This standard is crucial for robots that operate in safety-critical applications.

3. ANSI/RIA R15.06

In the United States, the Robotic Industries Association (RIA) has established ANSI/RIA R15.06, which provides safety requirements for industrial robots and robot systems. This standard is widely recognized and often referenced in certification processes.

4. CE Marking

In Europe, robots must often bear the CE mark, indicating compliance with EU safety standards. This marking is essential for manufacturers looking to sell their robots in European markets.

The Impact of Certification on Ownership

Understanding robot certification is vital for safe ownership. Here are some ways certification impacts robot owners:

1. Enhanced Safety

Certified robots are designed with safety in mind. Owners can operate these machines with greater confidence, knowing they have undergone rigorous testing and meet established safety standards.

2. Reduced Risk of Accidents

By using certified robots, owners can minimize the risk of accidents and injuries. This is particularly important in environments where humans and robots work side by side, such as manufacturing facilities.

3. Increased Reliability

Certified robots are generally more reliable than non-certified counterparts. Owners can expect better performance and fewer malfunctions, leading to increased productivity.

4. Legal Protection

In the event of an incident involving a certified robot, owners may have legal protections that non-certified robot owners do not. This can be crucial in mitigating liability and protecting business interests.

5. Access to Support and Resources

Many certification bodies offer resources and support to certified manufacturers and owners. This can include training, technical assistance, and updates on safety standards.

Choosing a Certified Robot

When considering the purchase of a robot, it's essential to look for certification. Here are some tips for selecting a certified robot:

1. Research Certification Bodies

Identify reputable certification bodies that are recognized in your region. Look for robots certified by these organizations to ensure compliance with safety standards.

2. Verify Documentation

Request documentation that verifies the robot's certification. This should include test results, design specifications, and any relevant compliance certificates.

3. Consider the Application

Different robots are designed for specific applications. Ensure that the robot you choose is certified for the intended use, whether it's for industrial, medical, or personal applications.

4. Evaluate Manufacturer Reputation

Research the manufacturer's reputation in the industry. Established manufacturers with a history of producing certified robots are often more reliable.

5. Seek Expert Advice

If you're unsure about the certification process or which robot to choose, consider consulting with experts in the field. They can provide valuable insights and help you make informed decisions.

The Future of Robot Certification

As technology continues to advance, the landscape of robot certification will likely evolve. Here are some trends to watch:

1. Increased Regulation

As robots become more integrated into everyday life, governments may introduce stricter regulations governing their use. This could lead to more comprehensive certification processes.

2. Focus on AI and Machine Learning

With the rise of artificial intelligence and machine learning, certification processes may need to adapt to address the unique challenges posed by these technologies. Ensuring the safety of autonomous robots will be a critical focus.

3. Global Standardization

As the robotics industry grows, there may be a push for global standardization of certification processes. This could simplify compliance for manufacturers operating in multiple countries.

4. Emphasis on Cybersecurity

As robots become more connected, cybersecurity will become a significant concern. Certification processes may need to incorporate cybersecurity assessments to ensure that robots are protected from hacking and other threats.

Conclusion

Understanding robot certification is essential for anyone looking to own or operate a robot safely. By ensuring that robots meet established safety standards, owners can protect themselves, their employees, and the environment. As technology continues to evolve, staying informed about certification processes and regulations will be crucial for safe and responsible robot ownership.

Take the next step in your journey by researching certified robots and understanding the certification process. Your safety and the safety of those around you depend on it.

Comments